Although Concrete has many advantages as a modern building material, including high strength, low cost, and ease of manufacturing, its production process emissions currently account for about 8% of global carbon dioxide discharges.

A recent study by a team from MIT suggests that introducing new materials into existing concrete manufacturing processes can significantly reduce carbon footprint without altering the volumetric mechanical properties of Concrete.

Concrete is the second largest consumer material in the world, second only to water, and is the cornerstone of modern infrastructure. However, during its manufacturing process, a large amount of carbon dioxide is released, which is both a chemical byproduct of cement production and the energy required for these reactions.

About half of the emissions related to concrete production come from the combustion of fossil fuels such as crude and natural gas, which are used to heat a mixture of limestone and clay, ultimately becoming the familiar gray powder commonly known as ordinary Portland cement (OPC). Although the energy required for the heating process can ultimately be replaced by electricity generated by renewable solar or wind energy, the other half of the emissions are inherent to the material itself. When the mineral mixture is heated above 1400 degrees Celsius (2552 degrees Fahrenheit), it undergoes a chemical transformation from calcium carbonate and clay to a mixture of clinker (mainly composed of calcium silicate) and carbon dioxide, which escapes into the air.

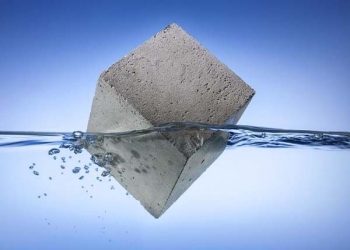

When OPC is mixed with water, sand, and gravel materials during concrete production, it becomes highly alkaline, creating a seemingly ideal environment for the fixation and long-term storage of carbon dioxide in the form of carbonate materials (a process known as carbonation). Although Concrete may naturally absorb carbon dioxide from the atmosphere, when these reactions typically occur, they mainly occur within Cured Concrete, which not only weakens the material but also reduces the internal alkalinity, thereby accelerating the corrosion of steel bars. These processes will ultimately damage the load-bearing capacity of the building and have a negative impact on its long-term mechanical performance. Therefore, these slow post-carbonation reactions can occur over several decades and have long been considered adverse pathways for accelerating concrete deterioration.

This composite material is a mixture of calcium carbonate and hydrated calcium silicate. Professor Admir Masik said, “It is a completely new material. In addition, through its formation, we can double the mechanical properties of early Concrete.” However, he also added that this research is still ongoing. “Although it is currently unclear how the formation of these new stages will affect the long-term performance of concrete, these new findings indicate an optimistic outlook for the development of carbon neutral building materials.”Lightweight Concrete Additives have brought many conveniences and advantages to the construction industry. By using this additive reasonably, architects and engineers can achieve more efficient, environmentally friendly, and personalized building designs.

The application of Lightweight Concrete Additives

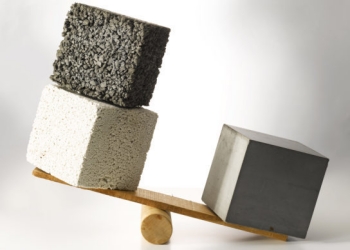

Lightweight: By adding light concrete additives, the density of Concrete can be reduced, thereby achieving lightweight components. This not only reduces the overall weight of the building but also helps to enhance the seismic capacity of the structure and reduce the foundation-bearing requirements.

Improving concrete performance: Additives can optimize the rheological properties of Concrete, making it more suitable for 3D printing. During the printing process, additives help maintain the stability of Concrete and prevent material blockage of the nozzle or segregation.

Enhanced thermal insulation performance: Lightweight concrete additives usually have good thermal insulation performance, which can significantly improve the insulation effect of components. This helps to decrease the energy consumption of buildings and achieve the goal of energy conservation and emission reduction.

Improving printing accuracy: The use of additives helps enhance the printability of Concrete, ensuring that printed components have higher accuracy and more complex shapes. This provides architects and designers with more excellent creative space.

Supplier

TRUNNANO(car-concrete.com) supplies lightweight concrete additives in Concrete, which are concrete and related products, with over 12 years of experience in nano-building energy conservation and nanotechnology development.

It accepts payment via Credit Card, T/T, West Union, and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality, lightweight concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).